IES Recommended Lighting Levels: Everything You Need To Know February 3, 2023 – Posted in: Lighting Information, Commercial Lighting, General Info

Table of Contents

Introduction to IES Lighting Levels & Applications

When it comes to creating the perfect lighting for any space, the Illuminating Engineering Society (IES) has you covered. The IES Lighting Recommendations are a set of standards designed to guide how much light should illuminate an object or surface to achieve comfortable, effective, and visually appealing lighting. These guidelines aren’t just about brightness—they also consider factors like contrast, color quality, and how light is perceived by the human eye.

Whether you’re lighting an outdoor area for safety, creating a cozy indoor atmosphere, or optimizing an office for productivity, IES standards provide a roadmap to ensure spaces are lit just right. By following these recommendations, you can create environments that are not only functional but also enhance the overall experience for everyone using them.

Furthermore, compliance with IES Lighting Standards have become increasingly important for energy conservation, since larger numbers of lumens can result in considerably higher electricity bills. The IES provides guidance based on the type of space and use so that users can make informed decisions about their needs.

There are lighting IES standards for commercial, industrial, health care, residential, and many other settings. Lighting designers often refer to these standards to make decisions on luminaires purchases.

Recommended Light Levels For Commercial Spaces

| Industry | Application | Foot Candles |

| Airplane Manufacturing | Drilling, riveting, screw fastening | 75 |

| Airplane Manufacturing | Final assembly, hangar | 100 |

| Airplane Manufacturing | Inspection | 50-200 |

| Airplane Manufacturing | Welding | 50 |

| Assembly | Rough easy seeing | 20-50 |

| Assembly | Rough difficult seeing | 50-100 |

| Assembly | Medium | 100-200 |

| Auditoriums | Social Activities | 5-10 |

| Auditoriums | Assembly Only | 10-20 |

| Auditoriums | Exhibitions | 15-25 |

| Automotive Manufacturing | Frame Assembly | 50 |

| Automotive Manufacturing | Body & chassis assembly | 100 |

| Automotive Manufacturing | Body parts assembly | 100 |

| Automotive Manufacturing | Final Assembly, finishing, inspecting | 200 |

| Banks | Lobby General | 10-50 |

| Banks | Writing Areas | 20-70 |

| Banks | Teller Stations, Posting & Keypunch | 50-150 |

| Barber Shop | Beauty Parlors | 50-100 |

| Chemical Works | Chemical Works | 30 |

| Clothing Manufacturer | Receiving, storing, shipping, winding, measuring | 20-50 |

| Clothing Manufacturer | Pattern making, trimming | 50-100 |

| Clothing Manufacturer | Shops, Marking | 50-200 |

| Clothing Manufacturer | Cutting, Pressing | 100-500 |

| Clothing Manufacturer | Sewing, Inspection | 200-500 |

| Electrical Equipment Manufacturing | Impregnating | 20-50 |

| Electrical Equipment Manufacturing | Insulating coil winding, testing | 50-100 |

| Food Service Facility | Dining areas, cashier | 20-50 |

| Food Service Facility | Cleaning | 10-20 |

| Food Service Facility | Dining | 5-20 |

| Food Service Facility | Food Displays | 30-100 |

| Food Service Facility | Kitchen | 50-100 |

| Foundries | Annealing Furnaces | 20-50 |

| Foundries | Cleaning | 20-50 |

| Foundries | Core Making | 50-200 |

| Foundries | Inspection Fine | 100-200 |

| Foundries | Inspection Medium | 50-100 |

| Foundries | Molding | 50-200 |

| Foundries | Pouring, Sorting | 50-100 |

| Garages-Motor Vehicles | Storage | 5 |

| Garages-Motor Vehicles | Parking Garage | 10 |

| Garages-Motor Vehicles | Service Garage | 10-20 |

| Garages-Motor Vehicles | Entrances | 50 |

| Garages-Motor Vehicles | Repair Area | 50-100 |

| Gymnasiums | Assemblies | 10 |

| Gymnasiums | General Exercise & Recreation | 30 |

| Gymnasiums | Exhibitions, Matches | 50 |

| Hospitals | Rooms | 10-30 |

| Hospitals | Corridors | 5-30 |

| Hospitals | Emergency Rooms | 50-100 |

| Hospitals | Operating Rooms | 100-200 |

| Hotels | Bathrooms | 20-50 |

| Hotels | Bedrooms for Reading | 10-20 |

| Hotels | Corridors, elevators and stairs | 10-20 |

| Hotels | Front Desk | 50-100 |

| Hotels | Linen Room: Sewing | 100-200 |

| Hotels | Linen Room: General | 10-20 |

| Hotels | Lobby: General Lighting | 10-20 |

| Hotels | Lobby: Reading and working areas | 20-50 |

| Iron & Steel Manufacturing | Stock, hot top, checker, cellar, calcining | 10-30 |

| Iron & Steel Manufacturing | Building, slag pits, Stripping yard | 20 |

| Iron & Steel Manufacturing | Control platform, repairs, mixer building | 30 |

| Iron & Steel Manufacturing | Rolling mills | 30-50 |

| Iron & Steel Manufacturing | Shearing | 50 |

| Iron & Steel Manufacturing | Tin Plate | 50 |

| Iron & Steel Manufacturing | Motor Room, Machine Room | 30 |

| Iron & Steel Manufacturing | Inspection | 100 |

| Library | Ordinary Reading, Stacks | 20-50 |

| Library | Book Repair and Binding | 20-50 |

| Library | Study & Notes, Cataloging | 20-100 |

| Library | Card Files, Check Desk | 20-100 |

| Laundries | Washing | 20-50 |

| Laundries | Ironing | 20-100 |

| Machine Shops | Rough Bench | 20-50 |

| Machine Shops | Medium Bench, Rough Grinding, Buffing | 50-100 |

| Machine Shops | Fine Bench and Work | 200-500 |

| Materials Handling | Loading Trucking | 10-20 |

| Materials Handling | Picking Stock Classifying | 20-50 |

| Materials Handling | Wrapping, Packing, Labeling | 20-50 |

| Offices | Accounting | 50-100 |

| Offices | Audio-Visual Areas | 20-50 |

| Offices | Conference Areas | 20-70 |

| Offices | Corridors, Stairways | 20 |

| Offices | Drafting | 50-200 |

| Offices | General and Private Offices | 50-100 |

| Offices | Lobbies, Lounges, & Reception Areas | 5-20 |

| Offices | Mail Sorting | 50-100 |

| Offices | Off-set printing & duplicating areas | 20-50 |

| Offices | Spaces with VDT’s | 75 |

| Paint Shop | Spraying, Rubbing | 20-50 |

| Paint Shop | Hand Art, Stencil | 20-50 |

| Paint Shop | Fine Hand Painting & Finishing | 50-100 |

| Paper Manufacturing | Beaters, Grinding | 20-50 |

| Paper Manufacturing | Finishing, Cutting | 50-100 |

| Paper Manufacturing | Hand Counting | 50-100 |

| Paper Manufacturing | Paper machine reel, Inspection | 100-200 |

| Paper Manufacturing | Rewinder | 100-200 |

| Printing | Welding | 50 |

| Printing | Color Inspecting | 100-200 |

| Printing | Presses | 50-100 |

| Printing | Proofreading | 100-200 |

| Printing | Composing Room | 50-100 |

| Schools | Reading | 20-100 |

| Schools | Typing | 20-100 |

| Schools | Demonstrations | 100-200 |

| Schools | Sewing | 20-100 |

| Sheet Metal Works | General | 100 |

| Sheet Metal Works | Tin Plate Inspection | 100-200 |

| Sheet Metal Works | Galvanizing, Scribing | 100-200 |

| Stores | Circulation Area Stockroom | 10-30 |

| Stores | Merchandising, Servicing | 30-100 |

| Stores | Merchandising, Self-Servicing | 200 |

| Textile Mills | Cotton Picking, Carding, Roving, Spinning | 50 |

| Textile Mills | Beaming & Slashing | 150 |

| Textile Mills | Drawing | 200 |

| Textile Mills | Others | 100 |

| Warehouse & Storage | Inactive | 5-10 |

| Warehouse & Storage | Active Rough Bulky | 10-20 |

| Warehouse & Storage | Active Medium | 20 |

| Warehouse & Storage | Active Fine | 20-50 |

| Welding | General | 20-50 |

| Woodworking | Sizing, planning, rough sanding, medium quality machine and bench work, gluing, veneering, cooperage | 20-50 |

| Woodworking | Fine bench and machine work, fine sanding and finishing | 50-100 |

| Woodworking | Rough sawing and bench work | 20-50 |

IES Recommended Light Levels For Residential Spaces

| Room | Foot-candles |

| Living Room | 10-20 |

| Bedrooms | 20-50 |

| Kitchen – General | 20-50 |

| Kitchen – Preparing / Cooking | 50-100 |

| Dining Room | 10-20 |

| Rooms for Difficult Reading & Writing | 50-100 |

| Bathrooms | 20-50 |

| Hallways | 5-10 |

| Basement / Garage Workshop | 20-75 |

| Basement – Laundry | 20-100 |

| Basement – Exercise and Recreation | 30 |

How to Achieve the IES Recommended Lighting Levels

Achieving the recommended levels can be done by using various tactics such as utilizing natural daylight, installing more energy efficient light fixtures such as LED lights, and using layered lighting. Natural daylight is one of the most important elements in creating a well-lit environment as it provides visual comfort and is also a key factor in boosting productivity.

Energy efficient solutions such as LED bulbs provide focused directional light while consuming fewer watts, which can help reduce energy costs while still providing sufficient illumination. Layered lighting combines multiple types of light sources (ambient, task and accent) to create an even distribution of balanced light that focuses on comfort, productivity and aesthetics.

The Benefits of Achieving the IES Recommended Lighting Levels

Achieving the Illuminating Engineering Society’s (IES) recommended levels can produce numerous benefits, both for a home and commercial environment. Not only does it help improve overall visibility and make occupants feel more comfortable, but it can also reduce energy consumption and help protect the environment.

A well-lit space is much easier to navigate, reducing accidents and therefore liability for the building owner. The improved design also increases productivity & efficiency due to fewer errors that might occur when people are in a dark environment or one with inadequate illumination. Finally, achieving IES-recommended standards can increase safety due to better ability to detect hazards such as slippery surfaces or items on the floor.

How Light Is Measured (Lux vs Foot Candles)

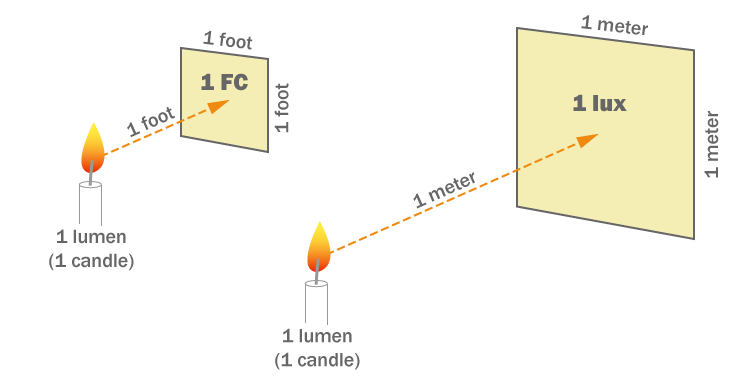

Understanding the differences between lux (lx) and foot candles (fc) measurement of light is paramount in ensuring that the lighting requirements of any given space are met. Lux measures how much light is spread over an area, while foot candles measure how much light is present in a single spot in an area.

For example; a 10-foot square room illuminated by ten 1W LED bulbs might have 500 lux however, it will only have 50 foot candles since each bulb only illuminates one spot at a time. Knowing which type of measurement to use for your environment is crucial when determining the illumination levels best suited for your location and application. The PDF below has an extensive list of spaces and applications with recommended foot candles taken straight from the IES Lighting Handbook.

IES Lighting Standards PDF

Frequently Asked Questions

What are the IES recommended lighting levels residential?

Standard lighting requirements for average residential illumination is 30 – 50 lumens. It gives the area a general lighting to be used mainly for finding your way around and executing normal activities. Ambient lighting should generate a pleasant degree of light and exude a feeling of serenity and roominess.

What are the lighting levels for IES parking lot?

For sheltered parking lots with average environments, IES advises least flat illuminance of 0.2 foot-candles, least vertical glow of 0.1 foot-candles and uniformity proportion at 20:1 maximum-to-least. With improved safety standards, IES proposes minimal horizontal gleam at 0.5 foot-candles, minimum vertical shine of 0.25 foot-candles and uniformity ratio of 15:1 maximum to lowest.

What are the recommended lighting levels for manufacturing?

For manufacturing facilities there is three separate standards, depending on the detail.

Rough Detail 50-75 foot candles

Medium Detail 75-100 foot candles

Fine Detail 100-150 foot candles

I have been the project manager for Modern.Place since early 2016, spending three of those years working overseas on the manufacturing & procurement side of the LED lighting industry. Constantly learning and passing on knowledge to others while excited for what the lighting industry will involve into next.